RENEWABLE ENERGY GENERATION INDUSTRY RENEWABLE ENERGY GENERATION INDUSTRY

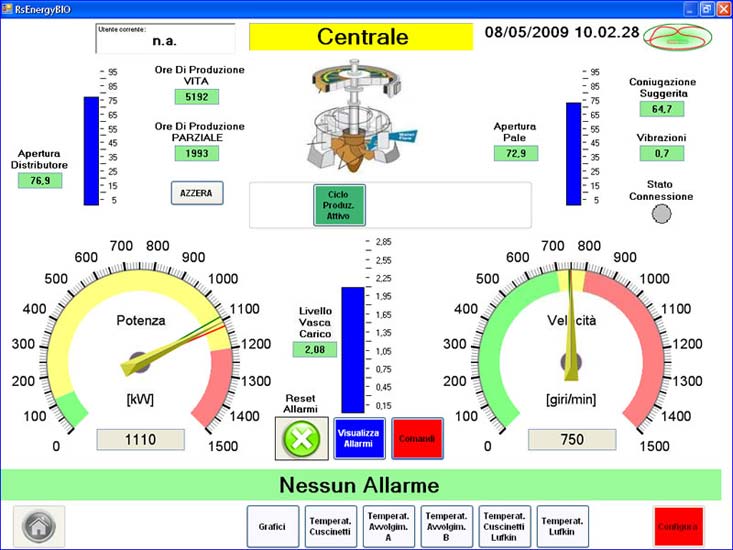

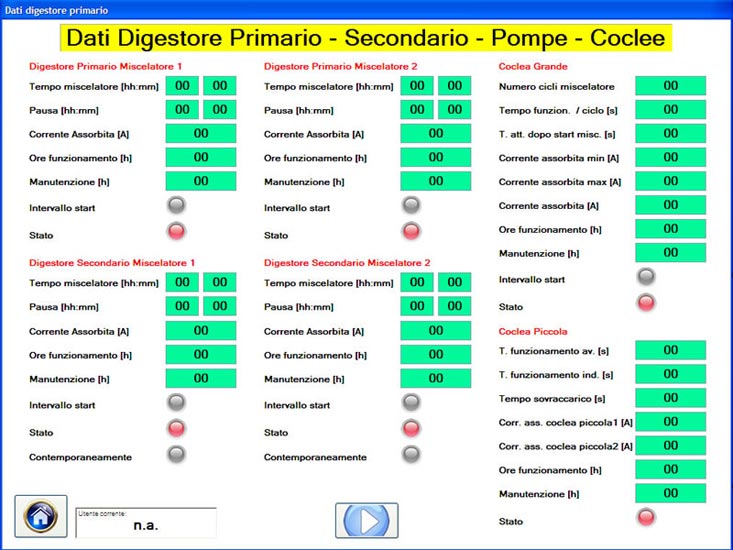

Construction and management of automation and supervision of the renewable energy generation station.

- Hydroelectric Turbine station.

- Hydroelectric Power auger station.

- Cogeneration plants.

- Photovoltaic plants.

|

PLASTICS PROCESSING INDUSTRY PLASTICS PROCESSING INDUSTRY

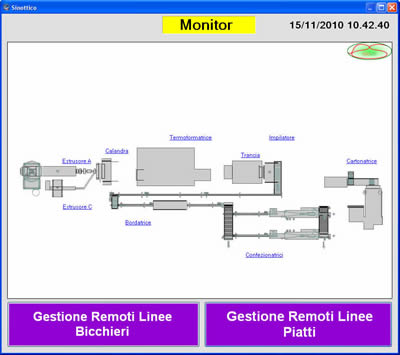

Construction and management of automation and supervision equipment for plastics processing.

- Mixing and Dosing Plants

- Plastic film extrusion lines

- Bending rolls

- Thermoformer

- Press

- Pliners grip plates

|

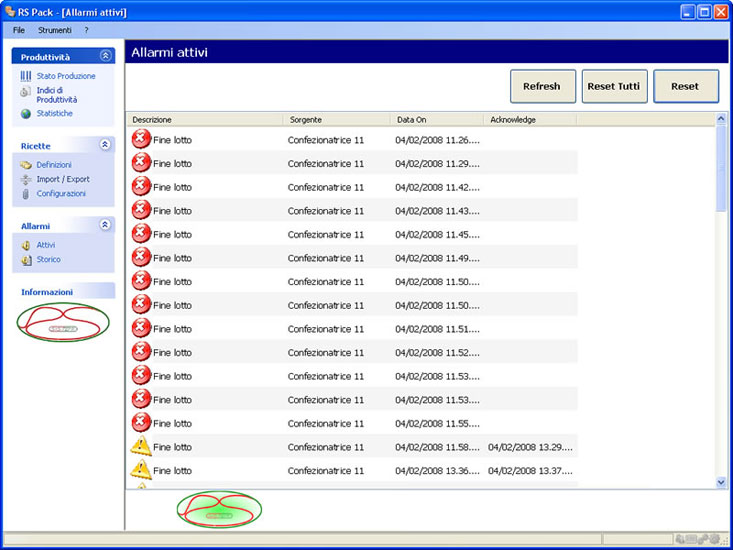

PACKAGING INDUSTRY PACKAGING INDUSTRY

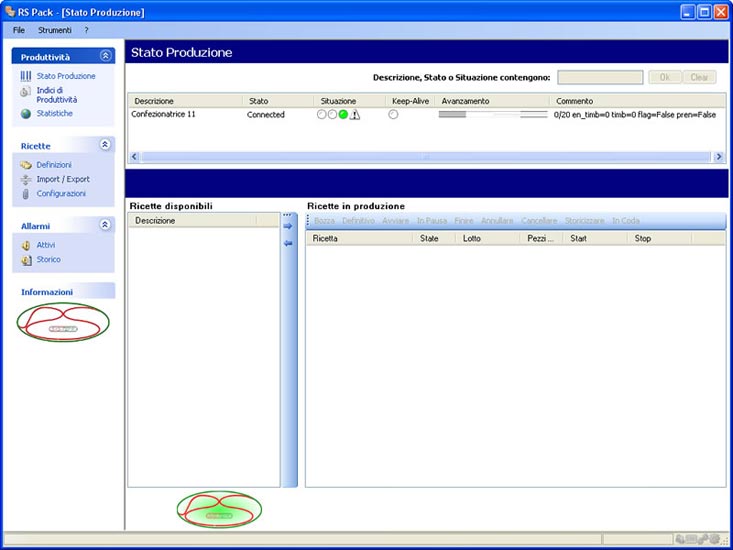

Construction and management of automation and supervision of packing and packaging systems:

- Vertical Packaging Machines

- Horizontal Packaging Machines

- Dosing plants

- Scales to multiple channels

- Dosing cups

- Multihead Weigher

- Thermoformer

- Casepackers

|

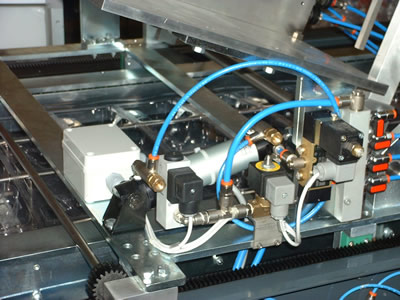

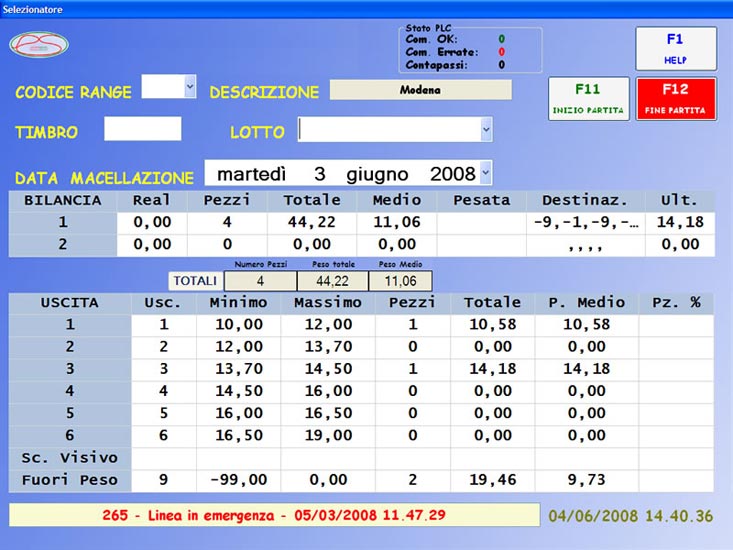

FOOD INDUSTRY FOOD INDUSTRY

Construction and management of automation and supervision of machines and processing lines for beef, especially beef and pork:

- Processing lines for cured fresh, cooked hams, fresh bacon, salami, speck.

- Processing lines for beef portions, splitting and butchering side of pork

- Lines of product selection

- Automatic system for handling racks on overhead rail

|

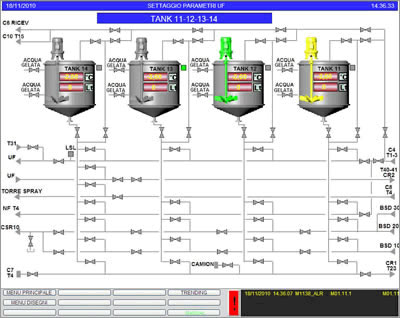

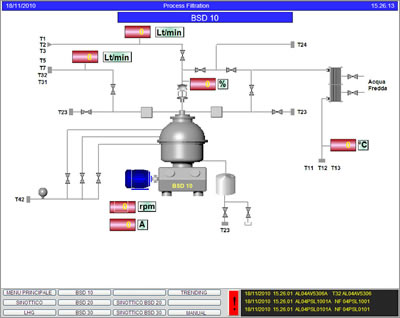

CHEMICAL INDUSTRY CHEMICAL INDUSTRY

Construction and management of automation and monitoring systems for the processing and production of blood products for the food, pharmaceutical and Zootechnical, such as Plasma, Globin, Emin and other specialty products, such as fertilizers derived from hemoglobin in agricultur.

- Processing for Ultrafiltration bovine blood and swine

- Processing for Nanofiltration bovine blood and swine

- Processing for extracion of Globin bovine blood and swine

- Processing for extracion of Plasma bovine blood and swine

- Processing for extracion of Hemin bovin blood and swine

|

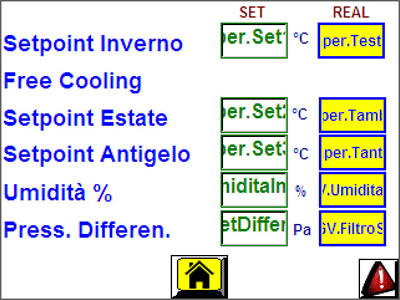

AIR HANDLING PLNATS AIR HANDLING PLNATS

Construction and management of automation and monitoring air handling plants.

- Plants of Air Conditioning

- Air handling (U.T.A.) systems

- Heat Exchangers systems

|

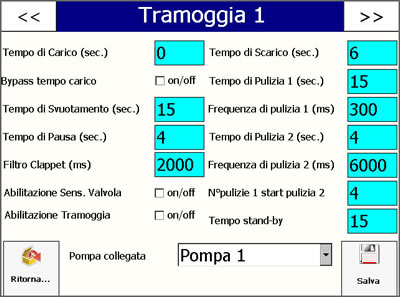

PNEUMATIC CONVEYING INDUSTRY PNEUMATIC CONVEYING INDUSTRY

Construction and management of automation and monitoring systems for pneumatic conveying for a variety of industries, including:

- Pharmaceutical sector

- Chemical and Cosmetics sector.

- Plastic sector.

- Packaging sector

- Ceramic sector

- Mechanical sector

- Food industry of Coffee

- Food industry of Sugar

- Food industry of Spices, seeds and herbs

- Food industry of Cocoa

|

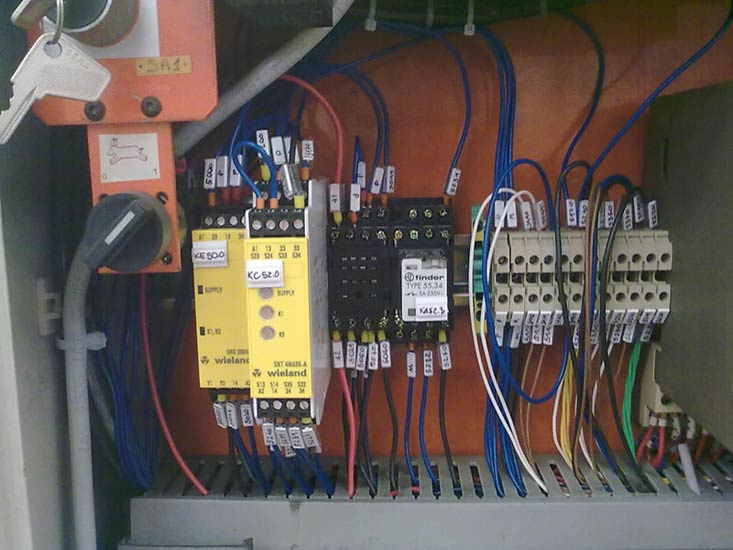

REVAMPING-RETROFITTING REVAMPING-RETROFITTING

Revisions process plant, from security to automation in various business areas.

- Revamping of station for the production of renewable energy

- Revamping of the Plastics processing lines

- Revamping of the Packaging lines

- Revamping of systems and production lines in the Food industry

- Revamping of processing system and production of blood products in the Chemical Industry

- Revamping of machines and processing plants in Mechanical/Metallurgical Industry

|